Contract Manufacturing Services

KNDS USA draws on more than 30 years of manufacturing experience to provide our customers with the quality and delivery they require. We focus on thoroughly understanding our customers’ requirements. Our team members are experienced, dedicated, and innovative in their pursuit of making our customers’ programs successful.

-

KNDS USA employs our expertise in machining, welding, assembly, testing, program management, quality management, manufacturing engineering, and other disciplines to ensure our customers’ products are delivered as intended. We have systems in place to comply with today’s security, import/export, quality, safety, and environmental standards. (CMMC, ITAR, EAR, ISO, OSHA, EPA, among others)

Our experience has primarily involved products and components used in the defense industry which are in use by militaries throughout the world. KNDS USA Inc. (KNDS) has established its resume as a manufacturer of military hardware for use by the US Army, Navy, and Marine Corps, as well as foreign military allies. The employees at KNDS USA’s state-of-the-art manufacturing facility have been producing Abrams Main Battle Tank (MBT) ammunition racks, gear boxes for the M777 lightweight towed howitzer, and/or two stage penetrating bomb components, as well as other military hardware for more than 30 years. KNDS USA’s pure manufacturing talents are enhanced by its history of design, program management, and product support.

The KNDS Group has designed, developed, and delivered some of the premier military vehicles on the planet. KNDS is the designer and developer of the Ammunition Racks used in the Abrams main battle tanks, and the Ammunition Racks used in the M10 Booker light tank.

KNDS USA has a long and proud history of performing “build to specification” sub-contract manufacturing for large defense contractors working on US and FMS programs, as well as directly for US government agencies. KNDS USA’s skillset makes it particularly well suited for industries requiring high quality and record keeping standards. The company possesses strong, diverse capabilities in areas such as: machining, welding, assembly, quality management, quality inspection, program management, engineering, import/export regulations, ITAR compliance, cybersecurity, and materials procurement. KNDS USA has established a well-managed and trustworthy supply chain for any needed outside services and is an ISO-9001 registered company.

-

a variety of turning and milling capabilities, including 3- and 4-axis machining, 9-axis multi-tasking, turning with live tooling, probing, and the use of magnetic fixturing.

the ability to machine very small parts weighing a few ounces to large parts weighing several tons, including parts as large as 3050mm (120in) wide, 4550mm (180in) long, and 1500mm (60in) tall.

experience working with many types of materials including zircaloy, titanium alloys, stainless steel, inconel, armor steel, tool steel, aluminium, brass, plastic, as well as other specialty materials.

experience working with many forms of raw materials including various types of extrusions, castings, forgings, rolled plate, weldments, and other forms.

capability of holding tolerances as close as .005mm (.0002in), true positions of .010mm (.0004in) and concentricity of .010mm (.0004in), with wire EDM capabilities of holding tolerances down to .003mm (.0001in)

deep hole boring up to 40 inches.

hard turning of material up to 62Rc.

capable of turning diameters from 4.5mm to 500mm (3/16in to 20in) and lengths up to 3,050mm (120in).

programmable hydraulic steady rests capable of holding diameters of 35mm to 310mm (1-3/8in to 12-3/16in) with repeatability of .01 mm (.004in).

the skill of machinists with more than 35 years of experience, combined with a path to empower younger skilled workers in gaining knowledge and experience.

Machining

-

precision mechanical assembly performed by skilled technicians that are experienced in proper fastener torquing, control of gear backlash, application of thread locking compounds, application of greases and lubricants, workstation and component cleanliness, and other assembly best practices.

using age-controlled chemicals and components.

maintaining part and material traceability.

diagnosing, repairing, and rebuilding damaged and/or worn assemblies.

technicians with more than 35 years of experience in mechanical assembly and repair.

wiring, soldering, and assembly of electrical and electronic control systems.

demonstrated ability to wire complex, interconnected assemblies, including the assembly and wiring of computer rack systems.

assembly of structures for simulator cabins using special lightweight construction techniques.

Assembly

-

GMAW (MIG) welding, including Spray and Pulsed modes of transfer.

GTAW (TIG) welding, including Semi-Automatic, Hot-Wire TIG welding.

Robotic MIG welding, torch reach up to 74in, push/pull capability for aluminum

welding small, intricate parts as well as large parts weighing several tons.

welding many types of materials including carbon steel, stainless steel, inconel, tool steel, aluminum, titanium, and others, including armor grades.

working with many forms of raw materials including various types of extrusions, castings, forgings, rolled plate, sheet, and other forms of material.

Purge Chamber (glovebox) for welding of reactive materials (Titanium, Zirconium).

utilizing high-purity gasses and various gas mixes to suit the material and design.

the development and qualification of Weld Procedure Specifications (WPS) and performing Welder Performance Qualification (WPQR).

welding performed to these standards: AWS D1.1 (Steel), D1.2 (Aluminum), D1.3 (Thin Steel), D1.6 (Stainless Steel), D1.9 (Titanium), D17.1 (Aerospace), B2.1 (General Qualification), TE&QA 3030, and various MIL and customer certifications.

work performed by welders with more than 25 years of experience.

Welding

-

is ISO 9001:2015 compliant and has been registered since January 15, 2001, under Amitvo certificate number 274323.

has demonstrated the ability to manage part and material traceability.

accurately measures large parts with laser tracker system - measurement volume exceeding 20ft³

makes use of high-precision Coordinate Measuring Machines (CMMs), and Portable Measuring Arms with non-contact laser, having a measuring envelope up to 6-1⁄2ft in diameter.

integrates CAD models into inspection programs used by CMM’s and Portable Measuring Arms.

has an environmentally-controlled metrology laboratory.

has the capability to perform and record first article inspections in accordance with AS9102.

maintains a full compliment of precision measuring instruments and hard gages.

has personnel trained and examined following SNT-TC-1A and NAS 410 for our dye penetrant inspection and magnetic particle inspection practices.

performs other non-destructive testing, including visual, hardness, plating thickness, and paint thickness.

employs quality inspection personnel with more than 25 years of experience in a manufacturing environment.

Quality

Example Programs

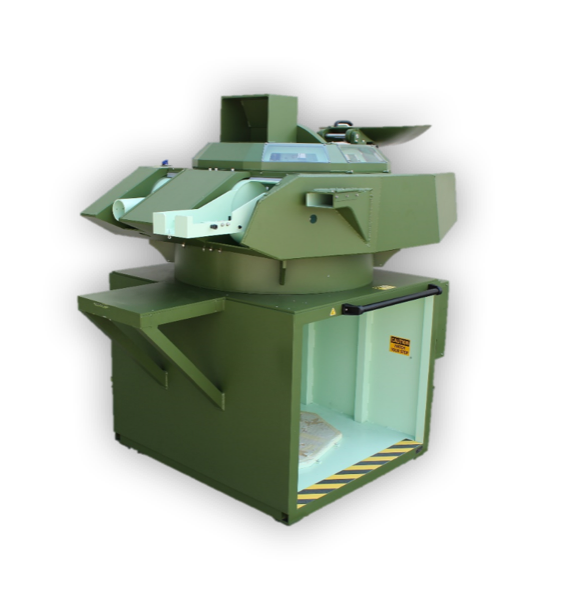

Ammunition Racks for Tanks

-

When the US Army committed to the formal improvement process of the Abrams MBT which increased the caliber of its main gun from 105mm to 120mm, the decision was made to incorporate the design concept from the German Leopard MBT for the new Abrams Ammo Racks. That design was a creation of the KNDS Group. KNDS, under the observation of TACOM, and the MBT prime contractor adapted the Leopard MBT design to the M1A1 Abrams MBT. KNDS continued to partner with TACOM, leading several significant redesign efforts which have continuously improved the design of the Ammo Racks for more than 35 years.

The KNDS Group is the only producer, ever, of complete, fully new, Ammunition Racks for Abrams series 120mm Main Battles Tanks. As such, we have been producing these Ammo Racks for more than 35 years. These systems have been produced in the same localities, with the involvement of many of the same assemblers, machinists, engineers, and program managers for many years.

KNDS USA expands on this tradition by applying our design and manufacturing expertise to the 105mm Ammunition Storage System for the M10 Booker light tank.

KNDS continues to produce Abrams Ammo Racks and “Ammo Rack Rebuild Kits” for military end users including the US Army and foreign Allies. KNDS is also in constant communication with our customers including the Abrams MBT Prime Contractor, the Anniston Army Depot (ANAD), and others, in order to maintain production readiness, and plan for continued procurement and processing of the raw materials required to meet their Ammo Rack needs.

Lightweight Howitzer

-

KNDS USA manufactures the traverse drive and elevation drive gearboxes, as well as many other components and assemblies used on the M777 Lightweight Howitzer. KNDS USA has produced components for more than 1500 guns in full rate production. KNDS USA continues to produce and deliver components for M777 spares support contracts.

KNDS began working on the M777 program in the pre-production stage where we demonstrated our ability to work with our customers to improve their products by suggesting design and manufacturing changes to enhance producibility, reliability, and performance.

Due to our consistent ability to meet customer needs, KNDS USA has taken responsibility for manufacturing an increased workshare on the M777 as the program has matured.

JoinT Stand-Off Weapon (JSOW)

-

KNDS USA has been manufacturing Follow Through Bomb Bodies, Hangers, and other associated components for the U.S Navy’s Joint Stand-Off Weapon (JSOW) program for or more than 15 years.

Perhaps the most interesting process KNDS developed for the JSOW program involved procuring 30ft long 12in diameter forged steel bars, sawing these in to 39in lengths which weight 800lbs each, from which we precision machine a 250lb bomb body involving tightly-controlled dimensions.

KNDS USA has used its strong, diverse capabilities in areas such as: machining, welding, assembly, quality management, quality inspection, program management, materials procurement, and import/export management to fulfill the requirements of the JSOW program.

Additionally, KNDS has worked closely with our well established and well managed supply chain for outside services, such as large component plating and specialty gun coat painting, to carry out the JSOW program.

APC Commanders Post

-

KNDS USA has manufactured the Commanders Post and Display Mounts for the Namer Armored Personnel Carrier.

KNDS has called on many of its manufacturing skills, from welder process qualification, to large-envelope machining, to test fixture development during the execution of this program.

Rocket Launcher

-

KNDS USA is a part of the team which manufactured the USMC SMAW Mod 2 (Shoulder Launched Multi-Purpose Assault Weapon). The SMAW MOD 2, system is comprised of a reusable composite matrix launch tube, an electro-mechanical firing mechanism, an on-board laser rangefinder, a LWIR thermal image sensor and a family of rockets (HEDP, HEAA, NE). It can be used on designated targets to destroy bunkers and other fortifications during assault operations, or to decommission Main Battle Tanks.

KNDS USA’s role on SMAW Mod 2 program was launch tube and firing mechanism manufacturer, and product final integrator.

Read Our KEY Equipment List

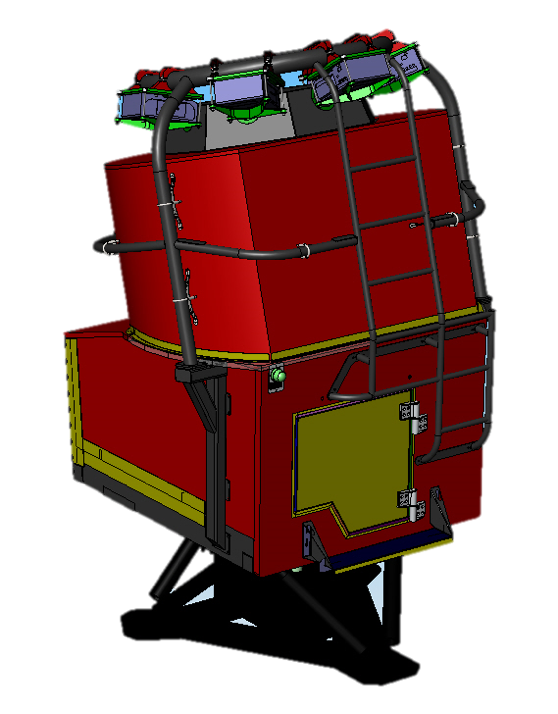

Training & Simulation

KNDS USA creates a wide variety of training systems from Classroom Trainers to High Fidelity Full Mission Trainers.

These trainers cover a multitude of training tasks, from individual tasks like Basic Driver and Gunnery Training to crew coordination, platoon, and battalion level simulations. These are all supported by one common simulation software package.

Systems designed by KNDS USA are based on a proven virtual and constructive simulation architecture which takes maximum advantage of existing systems (hardware and software) and standard industry interfaces. They leverage the investments made by the KNDS Group on numerous previously-delivered simulation training systems. These include the full range of man-in-the-loop training from desktop simulators to full motion high fidelity systems. These solutions deliver an advanced training system with state of the art technology that provides a robust, flexible solution that is reliable, easily maintained, and can be upgraded as necessary throughout the system’s life cycle.

For a more in-depth description of our capabilities, please download our Tech Overview (PDF).

Please view our capabilities video below.

Example Training Devices

AAV-TT

-

Proven Training Solution for the U.S. Marine Corps and Japan's Amphibious Rapid Deployment Brigade

The AAV-TT systems designed to deliver realistic, hands-on crew gunnery training for Assault Amphibious Vehicle (AAV) crews. These advanced trainers prepare both drivers and gunners for operational readiness while also supporting platoon-level and higher collective training exercises through system networking.

Training Value & Benefits

Aligned with USMC Gunnery Standards

The AAV-TT directly supports the "Gate-to-Live-Fire" gunnery training standard, as defined by TECOM MTSB. This ensures every Marine receives consistent, mission-focused training that translates into battlefield performance.

Safe, Efficient, and Cost-Effective

Virtual training reduces the need for costly live-fire exercises, fuel, and equipment wear—offering significant cost savings while minimizing risk and maintaining training quality.

Flexible and Scalable

Easily network multiple systems for collective training events, from individual gunnery drills to full platoon operations and joint missions.

Core Training Features

High-Definition Virtual Combat Environments

Realistic battlefield simulations that replicate mission conditions, from gunnery engagements to complex operational scenarios.

Intelligent Target & Weapon Effects Simulation

Targets behave and react like real threats; weapon effects mirror actual system performance for accurate training feedback.

Platoon & Joint Operation Capability

Trainers can link for large-scale, multi-unit exercises including joint service operations.

System Configurations

1. Institutional Version

• Out-of-hatch and under-hatch immersive view

• Full mechanical weapon and turret system simulation

• Ideal for permanent training centers

2. Containerized Version

• virtual below-hatch view

• Simplified weapon system simulation

• Highly mobile with minimal infrastructure requirements, perfect for rapid deployment or remote operations

Cost & Deployment Advantages

Lower Total Training Costs

Reduced ammunition, vehicle maintenance, fuel use, and range setup expenses.

Rapid Setup & Mobility

Containerized version offers quick fielding options anywhere training is required, without permanent facility investment.

Scalable for Any Mission Requirement

Adaptable for both small unit instruction and large-scale integrated operations.

Integrated KNDS Technology:

• KNDS Virtual Simulation Software Package

• Instructor Operator Station (IOS)

• After Action Review (AAR) Station

Ready for the Future of Amphibious Training

The AAV-TT platform lays a strong foundation for expansion into future simulation-based training programs, supporting evolving Marine Corps operational requirements.

LAV-DT

-

Our driving simulators offer a powerful way to train drivers, from basic skills to advanced maneuvers.

Here's what they can do:

• Cost-Effective Training: Save money on vehicle wear and tear and shorten training times. Trainees can practice tasks repeatedly in a short period, boosting efficiency.

• Safe Scenario Practice: Safely train for situations that are too difficult or dangerous to practice in a real vehicle.

• Immersive Driving: Feel like you're in a real vehicle with an exact replica of the driver's compartment (gauges, controls) and up to a high-fidelity 6 DoF motion system when necessary.

• Smooth Experience: Our precise visual system and dynamic motion feedback work together to significantly reduce motion sickness.

• Seamless Views: A curved projection screen creates a completely immersive environment for Out-the-hatch training, making trainees quickly feel like they're driving a real vehicle, or a more cost effective solution of simulating just the periscope for below hatch training.

• Diverse Environments: Train in a detailed virtual world featuring various terrains like cities, highways, deserts, and mountains.

• Interactive Scenarios: Practice alongside intelligent, AI computer-generated forces that interact with the trainee in the virtual environment.

Train for Critical Skills

Our simulators include a precisely replicated crew compartment, allowing training for:

• Individual & Team Maneuvering

• Command, Control, & Communication

• Emergency Procedures

• Vehicle Malfunctions

• Maneuvering the vehicle at its extremes

Integrated KNDS Technology

• KMW Ver.3 Simulation Software

• Simulated DVE (Driver's Vision Enhancer)

• Instructor Operator Station

• After Action Review Station

Stryker-GT

-

How It Elevates Soldier Proficiency

For military training, especially with complex vehicles like the Stryker, effective and realistic simulation is paramount. The Stryker Crew Gunnery Trainer (CGT) is a comprehensive system designed to ensure our soldiers are not just proficient in operating their weapon systems, but also highly coordinated as a cohesive crew. Here's a summary of its key aspects and how it directly benefits our training objectives:

System Overview: Focused on Combat Readiness

At its core, the Stryker GT is built to provide full crew gunnery training, with a laser focus on developing the skills of the gunner – the soldier directly responsible for the vehicle's primary weapon system. However, its capabilities extend far beyond individual proficiency, encompassing the entire crew for integrated combat readiness.

What it is:

• Authentic Replication: The system features a highly detailed, virtual re-creation of the Stryker's driver's compartment and the Common Remotely Operated Weapon Station (CROWS). This means soldiers train with controls that feel and respond just like those in a real Stryker, minimizing the learning curve when they transition to the actual vehicle.

• Multi-Weapon Versatility: The virtual CROWS RWS isn't limited to one weapon. It can accurately simulate the M2 (.50 cal machine gun), M240 (general-purpose machine gun), and MK19 (grenade launcher). This flexibility allows us to train on various weapon configurations without needing multiple physical trainers, optimizing our resources.

• Flexible Configurations: The Stryker GT can be set up in different ways, including a standalone Desktop trainer. This allows for individual practice and skill refinement, which is excellent for initial familiarization or refreshing skills without requiring a full crew setup.

How It Trains Our Soldiers: Building Cohesive, Lethal Crews

The true power of the Stryker CGT lies in its ability to train soldiers not just as individuals, but as an integrated, high-performing team ready for combat.

It trains soldiers by:

1. Immersive Crew Training: It provides an authentic environment for the entire crew – commander/gunner and driver. This means crew members can train together, learning to communicate effectively, anticipate each other's actions, and execute complex maneuvers as a single unit. The system includes a fully functional weapon simulator for the gunner and a simplified driver's station to ensure the driver is an integral part of the crew's training.

2. Mastering Gunnery and Combat Skills:

○ Basic to Advanced Gunnery: Soldiers develop fundamental individual handling skills and progress to complex crew gunnery exercises.

○ Emergency Procedures: Crews learn and practice critical emergency procedures, preparing them to react calmly and correctly under pressure in unexpected situations.

○ Weapon Malfunctions: A key feature is the ability to simulate weapon malfunctions. Instructors can inject various failures (like jams or misfires), forcing soldiers to troubleshoot and apply proper procedures, building resilience and problem-solving skills.

○ Realistic Visuals: Training includes simulated sights and vision blocks, ensuring soldiers learn to acquire targets and maintain situational awareness just as they would in a real Stryker.

3. Dynamic Scenario Generation:

○ Instructor Control: The Instructor Operator Station (IOS) gives instructors precise control over training sessions. They can manage normal weapon operations and, critically, introduce weapon malfunctions at any point to test the crew's reaction and problem-solving abilities.

○ Platoon-Level Exercises: A significant advantage is the ability to network the Stryker CGT with other gunnery/combat simulators. This allows for realistic platoon training, where multiple vehicle crews can operate together in a simulated tactical environment, practicing complex formations, coordinated engagements, and command and control. This goes beyond individual vehicle proficiency and builds true collective readiness.

Built on Reliable Technology

The Stryker CGT incorporates proven, Commercial Off-The-Shelf (COTS) products from KNDS USA. This includes the KMW Ver.3 Simulation Software, which forms the backbone of the system, along with simulated DVE (Driver's Vision Enhancer) and Simulated Periscope for enhanced visual realism. The use of COTS products often ensures robust performance, streamlined updates, and readily available support, which is a critical consideration for our long-term operational needs.

In summary, the Stryker Gunnery Trainer offers an unparalleled opportunity to train our soldiers and crews in a safe, cost-effective, and highly realistic environment, preparing them for the demands of modern combat operations.

Protector-RWT

-

It supports large groups of new gunners, plus refresher/qualification training for experienced gunners.

It can also be used for tactical training that includes section and platoon coordination.

The RWT is mixed-fidelity and set up as a desktop training.

The operator controls are simulated on a single touch-screen monitor Form fit and function tactical joystick.

If needed, the controls can be replaced with physical hardware.

Computer Generated Forces (CGF) used in the scenarios are controlled by the computer.

Example: the gunner can work with an “auto driver” that follows a pre-recorded route to complete a gunnery exercise.

Live Training

-

KNDS develops ruggedized targeting and positional sensor pods designed for tactical and surrogate weapon systems operating in demanding outdoor live-training environments. These pods deliver precise tracking, reliable data capture, and durable performance under realistic field conditions.

To support seamless integration, KNDS provides a fully documented Interface Control Document (ICD) for all sensor pods. This allows third-party training systems, applications, or range-control software to communicate directly with the pods—eliminating the need for custom software development and ensuring rapid, plug-and-play interoperability.

KNDS also designs and manufactures high-fidelity surrogate weapons—including FIM-92 Stinger, AT-4, M2, M240, and MK19 systems—that accurately replicate the form, function, and handling characteristics of their live counterparts. When paired with our advanced sensor technologies, these surrogates deliver safe, repeatable, and highly realistic live-force training across a broad spectrum of weapon platforms.

Instructor Operator Station

-

Easy to use Instructor Operator Interface for conducting and managing training:

Bird’s eye Stealth view and 2D and/or 3D map views

Comprehensive instructor and scoring tools

Drag & drop creation, on-the-fly modification, execution and rehearsal of exercises

Plug & play networking to other simulators for platoon, convoy, and combined arms training

Observation, record, and playback of simulated event

No exercise compilation required

Storage of exercises in structured exercise libraries is supported

Networkable using DIS/ HLA protocol

The training session for all KNDS simulators is controlled from an Instructor Operator Station (IOS).

The following displays are integrated:

Vehicle status information display

IMI® Graphical User Interface

Stealth view display

Daughter display of the student view

Surveillance camera to supervise the trainee inside the simulator cabin

Other controls for the instructor are

controls for activation and deactivation of the motion system including safety switches

a microphone and a touch-screen to control radio/intercom to communicate to the trainee

keyboard, mouse

a 3D “space” mouse to control stealth view

a printer

a speaker is integrated for the output of the sound-simulation and communication

A unique feature of the KNDS USA IOS is the addition of our student grading software. This is highly integrated with this training program and is able to score 95% of all of objective factors leaving only the small 5% of subjective factors up to an instructor to grade. This makes the training and grading extremely fair and fast allowing for a high-level of the student throughput.

KNDS virtual Simulation Software package

Our simulation environment is built entirely on an in-house codebase, giving us complete end-to-end control over every subsystem. With no dependencies on external vendors, we can modify, integrate, and expand capabilities precisely as mission requirements evolve.

-

One universal software framework

A single, cross-functional platform supports all KNDS simulators—driving, tabletop, and gunnery/combat—ensuring every training need is addressed within one coherent system.

Modular and scalable architecture

The framework can be tailored to any simulator configuration, allowing components to be added or adapted without restructuring the entire system.

Native networking (DIS over standard Ethernet)

Simulators connect seamlessly through the DIS protocol using standard Ethernet, requiring only simple configuration. This capability reflects more than 30 years of KNDS Training & Simulation expertise.

Optimized for standard COTS hardware

The entire software package runs reliably on off-the-shelf IT equipment, reducing costs, simplifying logistics, and maximizing uptime.

Field-proven reliability

KNDS USA training systems are widely deployed and recognized for their performance, effectiveness, and operational dependability.

Expanded Capabilities Across the KNDS Simulation Framework

Developed in collaboration with experienced military training experts worldwide, the KNDS simulation suite aligns directly with real-world operational needs:

Consistent, fair-fight Computer-Generated Forces (BATSIM)

All connected simulators share identical CGF visuals and behavior, ensuring true interoperability and realistic joint-operations training.

High-fidelity weapon-system modeling

KNDS’s deep expertise as a leading ground-based weapon-system manufacturer informs precise simulation of system logic, dynamic response, and real-world behavior.

Como: DIS-based radio and intercom simulation

Realistic voice communication environments support training in coordination and command procedures.

3D sound simulation

Directional audio enables trainees to perceive heading and distance for enhanced situational awareness.

Record & Replay with advanced AAR tools

Developed with Army instructors worldwide to support thorough debriefing, performance assessment, and structured learning.

Unified Instructor Management Interface (IMI)

A consistent interface across all simulators enables instructors trained on one system to operate any other KNDS device without additional preparation.

Integrated databases and MilCIG visual system

Harmonized data and KNDS’s high-performance MilCIG visuals provide maximum realism, quality, and responsiveness.

Dynamic Terrain

Proven KNDS technology accurately simulates terrain deformation and destruction—including artillery craters, structural collapse, and debris fields that alter mobility and tactical conditions.

Rich library of dynamic objects

High-detail objects allow instructors to build, enrich, and adapt scenarios with precision.